Top-Rated Polished Concrete Contractor

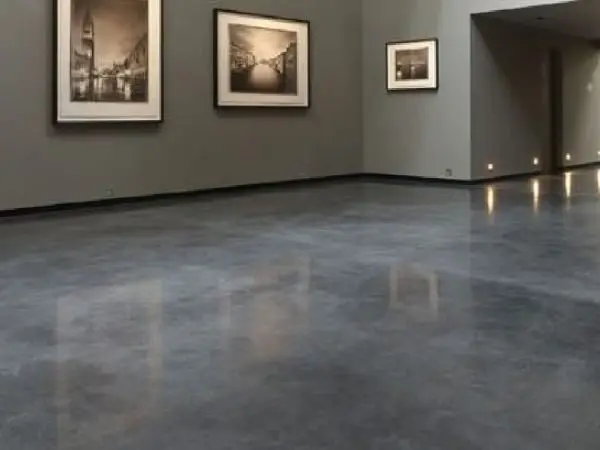

Polished concrete is one of the most eco-friendly floor systems on the face of the earth. Not only is polished concrete eco-friendly but it’s become the floor system of choice for hotels, retail, commercial, industrial facilities as well as high rises because of its durability and maintenance options. These floors also work in restaurant kitchens, schools, hospitals, and even homes. If you are located in NYC, it’s important to have a contractor that understands polished concrete and the steps involved in a true polish.

Polished concrete is created through honing the concrete. This means grinding the concrete down over and over again. A polished concrete floor can require anywhere from 6 to 12 passes from an industrial grinding machine with finer and finer diamond blades every pass over the concrete surface. In order to execute a proper polished concrete floor, your flooring company has to have the right equipment, technology, skilled labor and process. The end result is a beautiful floor system that is tough, durable, safe, easy to maintain, and aesthetically appealing.

Why choose Southside For your next Polished Concrete Project in NYC?

Every concrete floor is different and in manhattan, a lot of the buildings were built over 100 years ago. After our first phone conversation we collect information about your floor and start to understand the integrity of the concrete. We ask questions like, is there an existing coating on the floor? Has there ever been carpet on the floor? Is there glue, mastic or tiles that need to be removed? All of this information allows us to assess the floor and understand the machines and scope of work to get a perfect polish on your floor. concrete is a material usually made out of the combination of rocks, granite chips and river stones mixed with cement binder (either calcium sulfate or limestone) and water. Polished concrete in New York is a surface that is smooth surface and often decorative in nature.

Transforming concrete into polished concrete requires treating the concrete floor surface in your NYC establishment with a concrete densifier (chemicals that fill the pores of a concrete surface and make it harder). During the concrete grinding process. The floor surface is then prepared and allowed to dry. We then continue to grind the surface until the desired finish is achieved.

The level of sheen of polished concrete is measured by its grade and finish. A higher grade polished concrete in Nyc has more exposed aggregates and a higher gloss polish.

Choices for Polished Concrete

We have different options for every type of floor. If you are looking for the industrial look or just a retail polished concrete, there is a wide range of choices depending on its intended use and on your preference. These different polished concrete finishes provide a combination of durability, superb performance, and low maintenance. The level of the sheen of polished concrete floors (matte to high gloss finishes) depends on the diamond grit used. Aggregate exposure also varies from a cream finish (no exposure) to a full aggregate exposure.

Cream polish

This is the smoothest finish a polished concrete floor can achieve. It comes with the most consistent sheen as well. Colored finishes can be easily achieved with a cream polish because it easily and consistently adheres to stains and dyes.

Salt and pepper polish

This type of polished concrete floor is the easiest to achieve, making it the most popular. It easily adheres to stained Concrete and colors to achieve a perfect shine. Although minor imperfections such as small holes and cracks will be visible when the floor is done, they are able to create a unique and shiny look.

Aggregate polish

This is the least preferred of all the types of polished concrete. It is the most expensive to achieve because of some added processes. When done by highly skilled installers, an aggregate polished concrete floor can achieve an extremely desirable look. The choice of the type of polished concrete often depends on preference and purpose. There are instances where the condition of the concrete floor will dictate the type of polish that can be achieved. Usually, a cream polish cannot be achieved when coatings and glues have to be removed. When glues and coats need to be removed and ground, the cream polish will also be removed. It is important that clients know about these limitations.

Having a polished concrete floor installed provides a lot of benefits:

- Comes in matte to high gloss finish

- Dust free floors

- Seamless so there are no lines for dust and dirt to settle in

- Reflects light so there will be no need for additional lighting.

- Hypoallergenic because it is resistant to allergens ( dust and dust mites)

- Tough, durable and hard wearing

- Water and stain resistant

- Slip-resistant

- Reduces tire wear

- Easy to clean and maintain

- Low maintenance costs

- A good alternative flooring system to granite, marble, wood, tile, and linoleum.

- Highly affordable

- Long lasting

Adding a variety of colors to polished concrete through the application of concrete dyes and stains allows polished concrete floors to have a decorative look instead of the usual dull gray concrete floor.

Why Hire Professionals For Your Next Project in Manhattan (New York City)?

The Commercial concrete Polishing process is not as simple as it looks. Southside Concrete Polishing knows the right timing on when the steps should be done. Timing is crucial in the installation of polished concrete.

- Before pouring, air bubbles will be removed by vibrating the concrete.

- While pouring concrete, it will be leveled and incorporated into expansion joints to prevent cracking.

- A Power float (trowel machine) is used to create a smooth concrete floor surface which is done at the right time during the curing period when it is still a bit wet.

The entire polished concrete process takes more than a week to complete. The surface of the polished concrete floor needs to be protected against any possible damage and we need to have full access to the floor. This job is only for highly skilled and trained polished concrete installers. Polished concrete comes with a variety of options that can be customized. It is not only a great flooring option for commercial and industrial settings but for residential properties, too. As we detailed above, Southside Concrete Polishing uses a multi-step diamond polishing process to achieve a polished concrete floor that will provide texture and warmth no other flooring material can match. Polished concrete adds elegance to commercial and industrial spaces. When polished concrete is processed to a high gloss finish, it can mimic the look of granite or marble yet have its own unique personality. Our service area for polished concrete extends throughout all of NYC and NJ. We also handle stained concrete and epoxy floors. We look forward to working with you on your next project!